When it comes to maximizing the efficiency of your packaging process, understanding the ins and outs of horizontal wrapping machines is key. From the initial setup to troubleshooting common issues, mastering the operation of these machines can significantly impact your productivity. By following a few simple steps and being mindful of potential challenges, you can ensure a seamless wrapping experience that enhances your overall packaging workflow.

Machine Setup

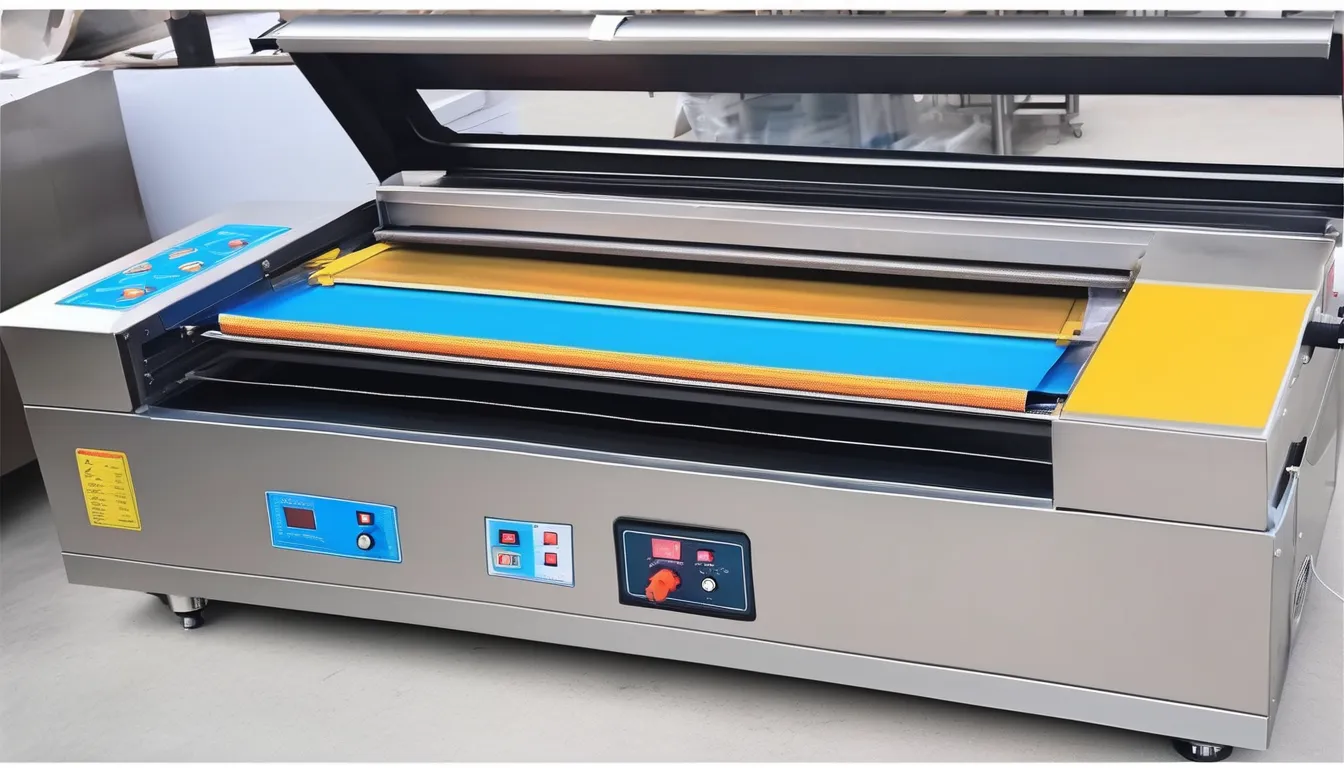

When setting up your horizontal wrapping machine, ensure that all components are securely in place before operation. Start by checking that the machine is on a stable surface to prevent any potential accidents during operation. Ensure that the power source is connected properly and that all safety features are functional.

Make sure the film roll is correctly loaded onto the machine, ensuring that it’s aligned properly for smooth wrapping. Adjust the settings on the control panel according to the specifications of the product being wrapped. Check that the sealing bar and cutting blade are in the correct positions and securely in place.

Verify that the conveyor belts are clean and free of any debris that could affect the wrapping process. Lastly, conduct a test run with a sample product to ensure that the machine is operating smoothly and that the wrapping is done correctly. By following these steps, you can ensure a successful setup of your horizontal wrapping machine.

Loading Products

Before loading products onto your horizontal wrapping machine, ensure that the machine setup has been completed according to the guidelines provided earlier. Once you have confirmed the setup, follow these steps to efficiently load your products:

- Prepare the Products:

- Make sure the products are organized and ready for loading.

- Check the quality of the products to avoid any issues during wrapping.

- Ensure that the products are aligned properly to prevent jams or miswrapping.

- Load the Products onto the Conveyor:

- Place the products on the conveyor belt according to the machine’s specifications.

- Maintain a steady flow of products onto the conveyor to keep the wrapping process smooth.

- Avoid overloading the conveyor to prevent damage to both the products and the machine.

- Monitor the Loading Process:

- Keep an eye on the products as they move through the loading area.

- Address any issues promptly to prevent downtime or damage to the machine.

- Ensure that the products are evenly spaced for consistent wrapping results.

Adjusting Settings

To optimize the performance of your horizontal wrapping machine, adjusting settings is crucial. Before starting the wrapping process, ensure that the settings are correctly configured to suit the specific requirements of your product.

Begin by adjusting the speed of the machine to match the desired wrapping pace. This can prevent issues such as tearing or overlapping of the wrapping material.

Additionally, set the tension control to the appropriate level to ensure a secure and consistent wrap around your product. Adjusting the temperature settings is also essential, especially when working with heat-sealable films, as it affects the seal quality.

Take the time to fine-tune the settings based on the type and size of the product being wrapped. Regularly monitoring and adjusting these settings as needed can help maintain the efficiency and quality of the wrapping process.

Once you have adjusted the settings, you’re ready to move on to the next step of starting the wrapping process.

Starting the Wrapping Process

Ensure your horizontal wrapping machine settings are finely tuned before proceeding with the wrapping process. Once everything is set up correctly, follow these steps to start the wrapping process smoothly:

- Load the Product: Place the item you want to wrap onto the infeed conveyor of the machine, ensuring it’s properly aligned and positioned for wrapping.

- Initiate the Wrapping Cycle: Activate the machine’s start button to begin the wrapping process. Observe the machine as it pulls the film and wraps it securely around the product.

- Monitor the Process: Keep an eye on the wrapping machine throughout the cycle to ensure that the wrapping is done correctly. Check for any issues like film tears, misalignment, or other irregularities that may affect the quality of the wrap.

Troubleshooting Tips

For optimal performance when using horizontal wrapping machines, it’s essential to be prepared to address any potential issues that may arise during the wrapping process. Here are some troubleshooting tips to help you overcome common challenges.

If you notice that the film isn’t properly adhering to the product, check the tension settings and adjust them accordingly.

In case the film keeps tearing during the wrapping process, inspect the film roll for any defects or replace it if necessary.

Should the machine start making unusual noises, stop the operation immediately and examine for any loose parts or obstructions.

If the machine’s sealing mechanism isn’t working correctly, verify the temperature settings and ensure they’re at the recommended levels.

Frequently Asked Questions

Can Horizontal Wrapping Machines Handle Irregularly Shaped Products?

Yes, horizontal wrapping machines can handle irregularly shaped products. They are designed to accommodate various shapes, providing efficient packaging solutions. You’ll find that these machines can securely wrap items of different sizes and forms.

What Is the Average Lifespan of a Horizontal Wrapping Machine?

Horizontal wrapping เครื่องบรรจุแนวตั้ง typically last 10-15 years with proper maintenance. You can extend their lifespan by cleaning regularly, checking for wear and tear, and servicing them as recommended by the manufacturer.

Are There Specific Safety Precautions Operators Should Follow?

When operating a horizontal wrapping machine, follow specific safety precautions. Always wear protective gear, avoid loose clothing, and secure long hair. Never bypass safety features. Regularly inspect the machine for any defects and follow proper training protocols to prevent accidents.

Can Horizontal Wrapping Machines Work With Different Types of Wrapping Materials?

Yes, horizontal wrapping machines can work with various wrapping materials. Ensure you select the appropriate material for your packaging needs to achieve optimal results. Always follow manufacturer guidelines for compatibility and best practices.

How Often Should Maintenance Checks Be Performed on These Machines?

Perform maintenance checks on your horizontal wrapping machine regularly. Ensure smooth operation by scheduling checks monthly or as recommended by the manufacturer. Regular maintenance helps prevent breakdowns and ensures efficient packaging processes.

Conclusion

Now that you have mastered the basics of using horizontal wrapping machines, you can efficiently wrap your products with ease. Remember to always monitor the machine closely for any issues and address them promptly to ensure smooth operation. With proper setup, loading, adjustments, and troubleshooting, you can maximize the efficiency and effectiveness of your wrapping process. Happy wrapping!